Building a Space Capsule House has special problems. Supply chain troubles and higher material prices slow down production. These problems cause delays and raise costs, making it tough to meet needs. Solving these issues is key to keeping this new housing idea possible for the future.

Key Takeaways

Problems in getting supplies and higher material prices slow space capsule house production. Factories need more suppliers to reduce these problems.

Not enough workers in factories cause slower production. Factories should train workers to gain skills and work faster.

Using green materials and new tech, like 3D printing, can cut costs and make production quicker. Factories should use these ideas to stay ahead.

Space Capsule House Manufacturing: An Overview

What Are Space Capsule Houses?

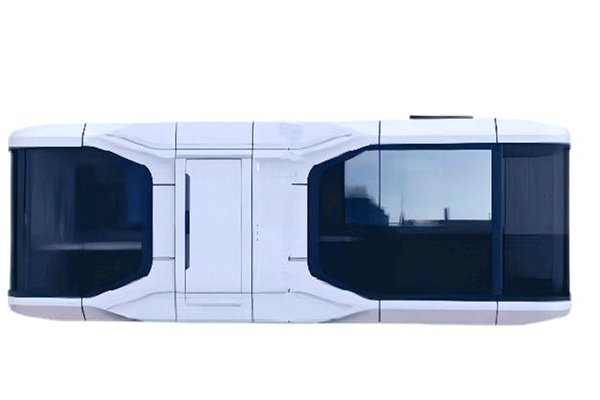

Space capsule houses are a new way to build homes. These small, modular houses are inspired by spacecraft designs. They focus on being strong, efficient, and flexible. Unlike regular homes, they are built in factories, which saves time and reduces waste. Their modern look includes curved walls, simple interiors, and smart technology.

Many things affect how they are made and their cost. For example, where they are built changes land prices and rules. Bigger or custom designs cost more money. Below is a table showing key factors that impact space capsule house production:

Materials and Technology in Space Capsule Houses

Making space capsule houses uses advanced materials and methods. Modular building speeds up the process and cuts waste. Strong materials like steel and concrete make these homes last longer. Eco-friendly choices, like recycled wood and safe paints, help the environment.

New technology also improves production. Robots and 3D printers make building faster and more exact. Smart home systems save energy and improve living. These upgrades make space capsule houses a smart choice for today’s housing needs.

Special Challenges in Manufacturing

Building space capsule houses has unique problems. The process needs careful planning and skilled workers. Using high-tech materials and tools requires experts, which can be hard to find. Since these homes are modular, supply chain delays can slow everything down.

"Challenges begin on Earth with building, moving, and testing. Launching creates strong vibrations, heat, and shocks. In space, materials face extreme temperatures, radiation, and debris."

This quote talks about space challenges but shows how hard it is to design tough structures. Space capsule houses don’t face space conditions but still need strong materials and careful engineering to work well.

Supply Chain Problems and Rising Material Costs: Main Reasons

Global Connections and Limited Resources

Factories, including those making space capsule houses, depend on global trade. This reliance causes problems when disruptions happen. Natural events like floods or earthquakes can stop work and block supplies. Political issues and strict trade rules make moving goods harder. For instance, sudden tariffs or bans can delay deliveries and raise prices.

Shortages of raw materials are another big issue. Important items like steel, concrete, and eco-friendly materials often come from a few suppliers. When demand is higher than supply, prices go up, and delays happen. Shipping problems, like crowded ports or late deliveries, make things worse. These issues show why it’s important to use multiple suppliers and regions.

Worker Shortages and Hard-to-Find Parts

Not enough workers is a major problem for factories. Many people have quit jobs, leaving industries short-staffed. In manufacturing, over 600,000 jobs are still open. About 75% of managers say finding skilled workers is their biggest challenge. This lack of skilled workers slows down making special parts for space capsule houses.

Getting these parts is also tough. High-tech materials and tools need trained workers, but fewer people have these skills. This makes production take longer and cost more. Factories need to train workers and use machines to fix these problems and stay efficient.

Money Problems and Inflation

Economic troubles raise material costs. Higher wages and pricier raw materials make production more expensive. Shipping costs have also gone up, adding to the problem. Supply chain delays make these issues worse, causing unstable prices and supplies.

Inflation makes things harder. Price indexes show costs rising everywhere. People expecting higher prices in the future add to inflation. A strong US dollar can cause inflation in poorer countries, raising costs for gas and oil. To handle this, factories must save money and find cheaper materials.

Impacts on Space Capsule House Production

Manufacturing Delays

Delays slow down making space capsule houses. Supply chain problems often cause these delays. Late deliveries of steel or eco-friendly parts stop production. Even small delays can lead to big problems. For example, missing modular parts can pause the whole assembly.

Worker shortages make delays worse. Factories struggle when skilled workers are missing. Training new workers takes time and adds to the problem. To stay on track, factories need faster systems and more machines.

Higher Costs and Price Problems

Rising material costs make these houses expensive. Steel, concrete, and other materials cost more due to high demand. These price increases make houses harder for people to afford.

Shipping costs also add to the problem. Expensive shipping lowers profits, so factories charge buyers more. This creates a tough choice: keep prices low or maintain quality. Factories should find cheaper materials and improve delivery systems.

Challenges for Growth and New Ideas

High costs and supply chain issues block growth and new ideas. Factories face long waits and uncertain demand. These problems make it hard to use new technology or grow production. For example, expensive shipping slows down scaling up operations.

Here’s a summary of key challenges:

Factories need better tools and more suppliers to solve these problems. These changes can help space capsule house production succeed in the future.

Solutions to Address Manufacturing Challenges

Spreading Out Supply Chains and Using Local Resources

Spreading out supply chains and using local resources lowers risks. Global problems like trade issues or disasters can stop production. By using suppliers from different places, factories avoid slowdowns. For example, companies now spread their suppliers to reduce risks. Depending less on a few suppliers also helps, but it needs good planning to manage costs.

Using local resources with tools like 3D printing speeds up production. It also cuts shipping costs and delays. This method is important to keep space capsule house production competitive.

Using New Materials and Eco-Friendly Methods

Using new materials and eco-friendly methods helps the planet and factories. Factories using renewable resources cause less harm to nature. For example, the circular economy reduces waste and protects habitats. Choosing eco-friendly materials is smart and good for the environment. Rules like the EU’s RoHS directive push for safer materials and new ideas.

Renewable resources lower harm to the environment.

Circular economy ideas reduce waste and protect nature.

Rules like the EU’s RoHS directive promote safer material use.

Eco-friendly factories follow rules and act responsibly.

Eco-friendly methods also get support from governments. This helps small factories grow while meeting environmental rules.

Using High-Tech Tools for Better Production

High-tech tools make factories faster and more reliable. Smart factories use data to fix machines before they break. Tools like IoT sensors and AI systems improve machine performance by 30%. Robots also handle boring tasks, making work faster and with fewer mistakes.

Smart Factories: Use data to fix machines before they break.

IoT Sensors: Watch machines in real time to avoid problems.

AI and Machine Learning: Save money and improve production.

Robotics Automation: Speed up work by handling simple tasks.

Supply Chain Optimization: Track supplies better and save money.

The market for fixing machines with data is growing fast. It could reach $15.9 billion by 2026. AI tools can save factories $532,000 an hour by stopping breakdowns. Real-time data also cuts repair costs by 40%. These tools are key to making space capsule houses faster and cheaper.

Supply chain problems and higher material prices slow production. But smart ideas and good planning can solve these issues.

Making things in space is a game-changer.

It helps create better products and boosts the economy.

The future of space capsule houses is bright. New materials and space technology will change industries and open doors to new ideas. By working together and thinking ahead, we can fix today’s problems and create a lasting solution for this cool housing idea. 🌟

FAQ

How are space capsule houses unique compared to regular homes?

Space capsule houses are built with modular designs and smart tech. They use strong materials and are eco-friendly, unlike regular homes.

Why do supply chain problems matter for making space capsule houses?

Supply chain problems slow down getting materials and raise costs. These issues make it harder to build on time and keep prices low.

What can factories do about rising material prices?

Factories can try new materials, use local supplies, and 3D print. These methods lower costs and reduce the need for pricey imports.