A prefabricated shipping container house offers a modern and eco-friendly way to live. These homes reuse materials sustainably, saving approximately 3,500 kg of steel per container. They are also affordable, with construction costs averaging $40,000–$60,000—up to 70% less than traditional houses. With over 14 million unused containers available, the possibilities are endless. By planning the shipping container conversion carefully, you can build a unique, energy-efficient home that reduces your carbon footprint by 80%. This innovative housing solution combines practicality with creativity.

Key Takeaways

Prefab shipping container homes are green and cost less, saving up to 70% compared to regular houses.

Good planning and expert help are needed to solve issues like strength and local rules.

You can create unique designs, but balancing cost and features is important.

Insulation and weatherproofing help keep the home comfy and save energy.

Check local building rules and get permits early to avoid delays and follow laws.

Understanding Prefabricated Shipping Container Houses

What Are Prefabricated Shipping Container Houses?

A prefabricated shipping container house is a home built using repurposed shipping containers. These containers, originally designed for transporting goods, are made of durable steel and adhere to strict international standards. For example, ISO/TC-104 and ISO 1496-1 ensure their strength and safety. Builders convert these containers into livable spaces by adding insulation, windows, doors, and other essential features. Prefabrication means that much of the construction happens off-site, which speeds up the building process and reduces waste.

These homes come in various sizes, depending on the type of container used. Standard containers are 20 or 40 feet long, offering flexibility in design. They can be used individually or combined to create larger spaces. Prefabricated shipping container houses are not only practical but also align with modern architectural trends, offering unique and innovative designs.

Why Are Shipping Container Homes Popular?

Shipping container homes have gained popularity for several reasons. First, they are an eco-friendly option. By reusing containers, we reduce waste and minimize the need for new construction materials. This aligns with the global push for sustainability. Second, they are affordable. Traditional housing costs have risen significantly, with a 57.8% increase in the House Price Index from 2019 to 2024. Container homes provide a cost-effective alternative, making homeownership more accessible.

Additionally, these homes cater to the growing demand for creative and innovative designs. Architectural firms like Gensler are leading the way in developing stylish, sustainable housing solutions. Rapid urbanization and rising housing prices have also contributed to their appeal. Governments, NGOs, and individuals are increasingly adopting container homes as a solution to housing shortages. The availability of unused containers further supports their affordability and quick construction.

Despite their advantages, it’s important to consider the disadvantages of container homes, such as limited space and potential structural challenges. However, with proper planning and professional guidance, these issues can be addressed effectively.

Key Cost Considerations

Cost of Converting a Shipping Container

When planning a shipping container home, understanding the cost of converting a shipping container is crucial. From my experience, the overall cost depends on the size of the project and the level of customization. For a basic single-container home, costs typically range from $25,000 to $80,000. Larger projects can exceed $100,000, especially if you want a multi-container design.

The costs involved in converting a shipping container include purchasing the container itself, materials, and labor. A used 20-foot container might cost between $1,500 and $3,000, while a new one could range from $2,500 to $5,000. Labor and materials for container home conversions can add another $10,000 to $50,000. Compared to traditional homes, which often cost over $400,000, shipping container homes are a more affordable investment.

Container Home Costs: Purchase and Delivery

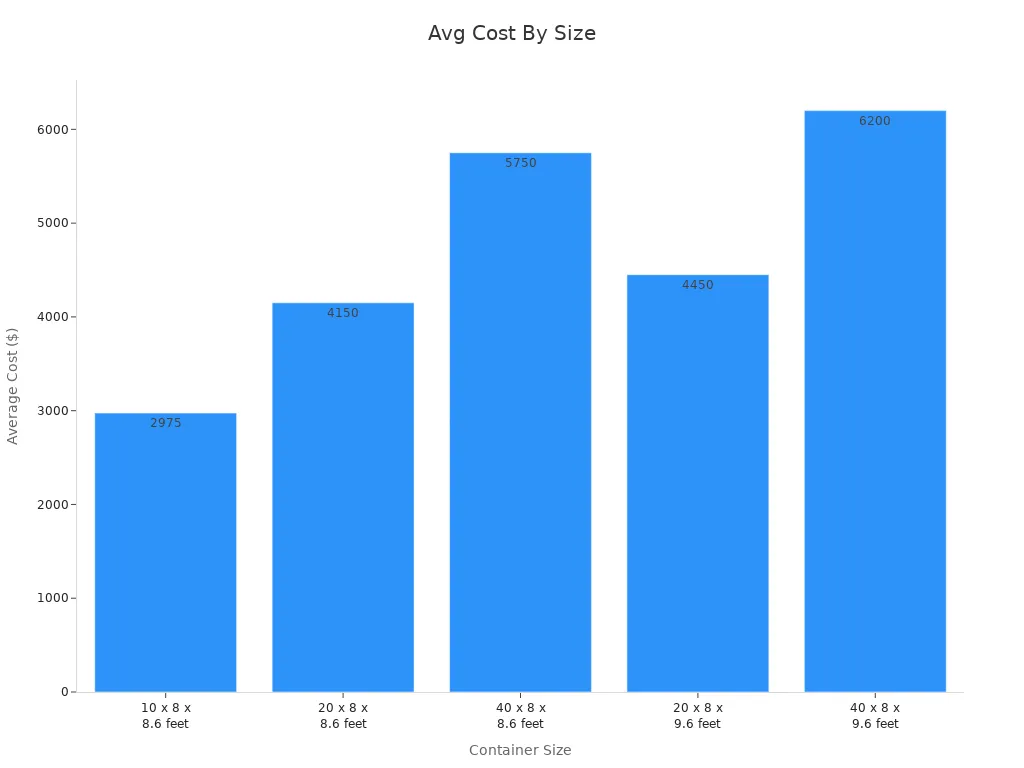

The purchase and delivery of containers form a significant part of the shipping container home budget. Based on current market data, here’s a breakdown of container costs:

Delivery fees also add to the budget. On average, delivery costs around $3,000, depending on the distance and location. I always recommend factoring in these costs early to avoid surprises.

Modifications and Customization Expenses

Modifications and customization expenses can vary widely based on your preferences. Basic modifications, such as cutting openings for windows and doors, typically cost between $2,000 and $5,000. Interior design and finishes, like flooring and paint, can add another $5,000 to $10,000 or more. Installing windows, doors, and fixtures might cost an additional $1,000 to $4,000.

From my perspective, balancing your budget with your desired level of customization is key. Prefabricated options are generally more affordable, costing $150 to $300 per square foot, while custom designs can range from $250 to $400+ per square foot. By planning carefully, you can create a unique home without overspending.

Labor and Construction Costs

Labor and construction costs play a significant role in container home conversions. From my experience, these costs vary depending on the location and complexity of the project. In rural areas, construction costs typically range from $150 to $300 per square foot. However, in highly regulated urban areas, these costs can rise to $300–$500 per square foot. For a high-end 20-foot container, material costs hover around $18,000, while labor costs add approximately $15,000. A more complex 40-foot container can cost $28,000 for materials, with labor expenses ranging from $25,000 to $40,000.

To manage your budget effectively, I recommend working with experienced builders who specialize in shipping container homes. They can help streamline the process and avoid costly mistakes. Additionally, prefabricated options often reduce labor costs compared to fully custom designs.

Permits and Zoning Fees

Navigating permits and zoning regulations is another critical step in container home conversions. Permit fees vary widely based on your location and the scope of your project. In my experience, these fees can range from a few hundred to several thousand dollars. Researching local building codes early in the planning phase is essential. Some areas may have restrictions on using shipping containers as residential structures, while others might require additional inspections or certifications.

I always advise consulting with local authorities or hiring a professional familiar with zoning laws in your area. This ensures compliance and prevents delays during construction. Remember, failing to secure the necessary permits can lead to fines or even the dismantling of your project.

Additional Costs: Insulation, Utilities, and Finishing

Insulation, utilities, and finishing stages significantly impact the overall cost of building shipping container homes. For insulation, you might spend $5–$10 per square foot for metal siding or $8–$20 per square foot for wood or composite materials. Plumbing installation costs range from $4,000 to $10,000, while wiring expenses include $1,500–$3,000 for materials and $2,000–$5,000 for labor. Basic appliances add $3,000–$5,000, but high-end models can exceed $10,000.

Finishing touches, such as doors and windows, also add to the budget. Cutting openings costs $100–$500 per cut, while fixtures range from $200 to $2,000 per item. By planning these expenses carefully, you can create a comfortable and functional home without exceeding your budget.

Design and Construction Factors

Design Flexibility and Aesthetic Options

Shipping container homes offer incredible design flexibility. I’ve seen how these homes can adapt to various lifestyles and preferences. For instance, they can be relocated easily, making them ideal for those who value mobility. The ability to customize both the exterior and interior allows homeowners to express their personal style. You can choose from a range of exterior finishes, such as wood, metal, or composite materials, to match your aesthetic vision. Inside, layouts can be tailored to maximize space and functionality.

Another advantage is the use of sustainable materials. Recycled shipping containers not only reduce waste but also contribute to eco-friendly construction. These homes can be built on different types of foundations, adding to their versatility. Features like insulation and energy-efficient windows enhance comfort and safety, proving that container homes are as practical as they are stylish.

Prefab vs. DIY: Choosing the Right Approach

When deciding between prefab and DIY container home construction, I always recommend weighing the pros and cons. Prefab options are generally 30% to 50% cheaper than traditional construction. They also save time, as they can be assembled quickly—an advantage in urgent situations like disaster relief. However, prefab homes may limit customization options compared to a fully DIY container home.

On the other hand, DIY projects allow for complete creative control. You can design every detail to suit your needs. But DIY requires significant time, effort, and expertise. Skilled labor is essential to ensure structural integrity and compliance with building codes. For those new to construction, prefab homes might be the better choice due to their efficiency and lower environmental impact.

Stacking and Combining Containers

One of the most exciting aspects of container homes is the ability to stack and combine units. Shipping containers are designed to withstand heavy loads, making them ideal for multi-level designs. I’ve come across projects where containers were stacked to create stunning, modern homes with multiple floors. Combining containers horizontally also allows for larger living spaces, perfect for families or shared housing.

Structural assessments are crucial when stacking or modifying containers. Reinforcements may be needed to maintain stability, especially for multi-level designs. This approach not only maximizes space but also contributes to sustainability by reusing materials. The adaptability of containers makes them a cost-effective and innovative solution for residential projects.

Hiring Experienced Builders for Shipping Container Homes

Hiring experienced builders for shipping container homes can make a significant difference in the success of your project. From my experience, skilled contractors understand the unique challenges of container construction. They know how to handle structural modifications, insulation, and weatherproofing effectively. This expertise reduces the risk of costly mistakes and ensures the project stays on track.

One major advantage of working with experienced builders is efficiency. They often require less supervision, allowing you to focus on other aspects of the project. I’ve noticed that contractors who specialize in container homes tend to deliver higher-quality work. They align their efforts with your vision, ensuring the final result meets your expectations.

Tip: Always check a builder’s portfolio and references before hiring. This helps you assess their experience and reliability.

Here are some benefits of hiring experienced builders:

They streamline the construction process, saving time and resources.

Their knowledge of container-specific requirements prevents errors.

They produce work that adheres to your design and quality standards.

For those considering a diy approach, I recommend weighing the pros and cons carefully. While diy projects offer creative freedom, they demand significant time and expertise. Without proper skills, you might face challenges that delay the project or increase costs. In contrast, experienced builders bring the technical know-how to handle complex tasks efficiently.

Investing in professional builders ensures a smoother construction process and a durable, well-designed home. It’s a decision that pays off in the long run.

Insulation and Weatherproofing

Insulation Options for Prefabricated Shipping Container Houses

Insulating a shipping container home is essential for maintaining a comfortable indoor environment. From my experience, choosing the right insulation depends on factors like climate, budget, and personal preferences. Common options include spray foam, fiberglass, and insulated panels. Spray foam provides excellent thermal efficiency and seals gaps effectively, while fiberglass is a cost-effective choice for moderate climates. Insulated panels, though more expensive, offer superior energy savings over time.

Some homeowners opt for alternative methods, such as green roofs or radiant barriers, to complement traditional insulation. Green roofs not only improve thermal performance but also enhance the home’s aesthetic appeal. Radiant barriers, on the other hand, reflect heat away, making them ideal for hot climates. For those seeking a simpler solution, pre-insulated shipping containers can save time and effort during construction.

Weatherproofing for Durability and Comfort

Weatherproofing ensures that your container home withstands harsh conditions while remaining comfortable. I’ve found that exterior cladding, made from durable materials like PVC or composite panels, protects against weathering and corrosion. Proper sealing around windows and doors prevents water leaks, which can lead to rust or mold. Adding a weather-resistant roof coating further enhances durability.

For long-term protection, consider installing energy-efficient features like solar panels and LED lighting. These not only reduce energy costs but also contribute to environmental sustainability. By combining insulation and weatherproofing, you can create a home that is both durable and energy-efficient.

Managing Temperature and Moisture Challenges

Managing temperature and moisture in container homes requires careful planning. In tropical climates, high humidity can cause condensation inside the container. I recommend using dehumidifiers and proper ventilation systems to address this issue. Insulation also plays a key role in preventing moisture buildup by maintaining a stable indoor temperature.

Case studies highlight the importance of selecting the right materials. For example, research in Leyte, Philippines, shows how insulation and ventilation improve thermal performance in humid environments. Another study in Port Said compares various insulation materials, emphasizing their effectiveness in managing temperature and moisture. These findings underscore the need for tailored solutions based on local climate conditions.

Tip: Always consult professionals to ensure your insulation and weatherproofing choices align with your region’s climate.

Permits and Zoning Regulations

Researching Local Building Codes

Understanding local building codes is the first step in any shipping container home project. I’ve learned that these codes outline structural and safety requirements, including specifications for materials, foundations, and systems like plumbing and electrical. Each region has unique codes, so thorough research is essential. For example, in California, earthquake resistance and fire safety are critical considerations due to natural disaster risks. Early engagement with local building authorities can help clarify these requirements and prevent delays.

Building code inspections occur at various stages of construction to ensure compliance. Missing these inspections can lead to costly setbacks. I always recommend creating a checklist of local requirements to stay organized. This approach ensures your project aligns with all legal standards.

Obtaining Necessary Permits

Securing permits is a fundamental step in container home construction. Permits confirm that your project complies with local building code and zoning requirements. From my experience, the permitting process varies by location. Some cities have straightforward procedures, while others require multiple approvals. For instance, in urban areas, additional permits may be needed for utilities or environmental impact assessments.

I’ve found that working with professionals familiar with local regulations simplifies this process. They can guide you through the paperwork and ensure all necessary documents are submitted on time. Without proper permits, you risk fines or even project termination. Taking the time to secure permits upfront saves headaches later.

Navigating Zoning Restrictions for Shipping Container Homes

Zoning restrictions significantly impact the feasibility of container home projects. Local authorities determine allowable land uses, which vary by region. For example, some areas classify container homes under residential zoning, while others may restrict them to commercial or industrial zones. Checking these restrictions early helps avoid costly mistakes.

Visual impact and environmental considerations also play a role. Planning authorities often assess how container homes blend with their surroundings. In my experience, addressing these concerns proactively improves approval chances. By understanding zoning laws and adapting your design accordingly, you can ensure your project moves forward smoothly.

Challenges and Solutions

Structural Stability and Reinforcement

Ensuring structural stability is one of the most important aspects when building a shipping container home. Containers are designed to carry heavy loads during transport, but modifications like cutting openings for windows and doors can weaken their structural integrity. I always recommend reinforcing these areas with steel beams or frames to maintain strength. For multi-level designs, additional support is necessary to handle the weight of stacked containers.

A study titled Container Homes Research Project highlights the importance of structural assessments. It suggests that connecting containers properly and using reinforcements can address stability concerns effectively. This approach ensures the home remains safe and durable over time.

Addressing Toxic Paints and Materials

Shipping containers often come with industrial-grade paints and coatings that protect them during transport. However, these materials may contain toxic chemicals, posing health risks if not handled properly. I always advise removing the original paint and applying non-toxic, eco-friendly coatings. Sandblasting is an effective method for stripping old paint, followed by priming the surface with safe alternatives.

Additionally, some containers may have been used to transport hazardous materials. It’s crucial to inspect and clean them thoroughly before use. Following local regulations ensures the home is safe for occupants. By taking these precautions, you can build a healthy and sustainable living space.

Managing Limited Room Sizes

Limited room size is a common challenge in container homes. Maximizing space requires creative solutions. I’ve found that vertical space optimization works wonders. Designing lofted areas, installing tall cabinets, and adding hanging systems can enhance functionality without consuming floor space. Multi-functional furniture also plays a key role. Convertible sofas, modular systems, and sliding panels make compact areas more versatile.

The Container Homes Research Project study emphasizes connecting containers to create larger spaces. Combining this with smart layouts ensures a comfortable living environment. Here are some practical tips for managing small spaces:

Use lofted beds or storage units to free up floor space.

Invest in furniture that serves multiple purposes, like a sofa bed or a dining table with storage.

Incorporate sliding doors to save space compared to traditional hinged doors.

By applying these strategies, you can build a home that feels spacious and functional despite its compact size.

Solutions for Common Challenges in Container Home Construction

Building a shipping container home comes with unique challenges, but I’ve found that most issues have practical solutions. Here are some common problems and how to address them effectively:

Structural Weakness After Modifications

Cutting openings for windows and doors can weaken the container’s structure. To solve this, I recommend reinforcing these areas with steel beams or frames. This ensures the container remains stable and safe, even after significant modifications.Insulation and Temperature Control

Containers can become extremely hot or cold due to their metal construction. I’ve seen great results using spray foam insulation, which provides excellent thermal efficiency. Adding ventilation systems and energy-efficient windows also helps maintain a comfortable indoor environment.Compliance with Local Regulations

Navigating building codes and zoning laws can be tricky. I always advise researching local regulations early in the planning phase. Consulting professionals familiar with container home projects can save time and prevent costly mistakes.Limited Space

Maximizing space in a container home requires creativity. I suggest using multi-functional furniture, like sofa beds or foldable tables. Vertical storage solutions, such as tall cabinets or lofted areas, can also make a big difference.

Tip: Always work with experienced builders who understand the unique requirements of container homes. Their expertise can help you avoid common pitfalls and build a durable, functional home.

By addressing these challenges head-on, you can build a container home that meets your needs and complies with all necessary regulations. With proper planning and the right team, these homes offer a sustainable and innovative housing solution.

Building a prefabricated shipping container house offers a unique opportunity to create a sustainable and cost-effective home. These homes stand out for their adaptability, durability, and eco-friendly nature. They reduce landfill waste by repurposing steel containers and minimize environmental impact with quieter, cleaner construction processes. With proper planning, you can manage costs effectively and design a home that suits your lifestyle.

I always recommend consulting professionals to navigate container home building logistics, including permits and structural modifications. Researching thoroughly ensures compliance with local regulations and helps avoid unexpected challenges. Whether you choose a prefab or DIY approach, shipping container homes provide a versatile solution for modern living. Their ability to withstand harsh weather conditions and adapt to various designs makes them a reliable choice for container home living.

Tip: Start with a clear budget and prioritize insulation, weatherproofing, and structural stability to build a durable and comfortable shipping container home.

FAQ

What are the benefits of using shipping containers for homes?

Shipping containers offer durability, affordability, and sustainability. They are made of strong steel, making them resistant to harsh weather. Reusing containers reduces waste and supports eco-friendly construction. Their modular design allows for creative layouts and quick assembly, saving time and resources.

How do I ensure my container home is energy-efficient?

I recommend using spray foam insulation for thermal efficiency. Install energy-efficient windows and doors to reduce heat loss. Solar panels and LED lighting can further lower energy consumption. Proper ventilation systems also help maintain a comfortable indoor environment while conserving energy.

Are shipping container homes safe to live in?

Yes, they are safe when built correctly. Reinforce structural modifications like window and door openings with steel beams. Use non-toxic paints and coatings to avoid health risks. Proper insulation and weatherproofing ensure comfort and protection from extreme temperatures and moisture.

How long does it take to build a container home?

The timeline depends on the project’s complexity. Prefabricated container homes can be ready in 2–3 months. Custom designs may take 6–12 months due to additional modifications and permits. Hiring experienced builders speeds up the process while ensuring quality.

Can I build a container home on any type of land?

Not all land is suitable. Research local zoning laws and building codes to confirm if container homes are allowed. Some areas may require specific permits or have restrictions. Consulting local authorities ensures compliance and avoids legal issues during construction.