Key Takeaways

Container homes may cost $25,000 to $250,000 in 2025. Plan well to avoid extra expenses.

Buying used containers saves money and helps the environment. Think about this for your build.

Simple designs cost less and are built faster. Use the container's original shape smartly.

Cost Breakdown

Shipping Container Purchase

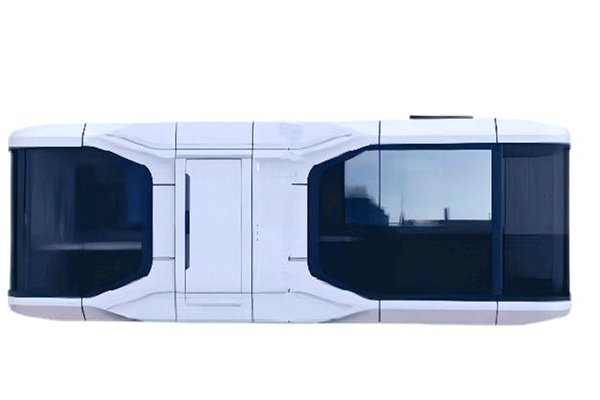

When planning your shipping container home, the first expense is the container itself. Prices vary based on size, condition, and type. For example, a 20-ft. standard used container costs around $2,100, while a new one can reach $3,000. High cube containers, which offer extra height, cost slightly more. A 40-ft. high cube container can range from $2,850 (used) to $5,800 (new). The number of containers you need depends on your design. A studio might require just one, while a 4-bedroom home could need six.

With container prices rising by over 55% since 2016, sourcing affordable options requires careful research.

Modifications and Structural Changes

Transforming a shipping container into a livable space involves modifications. Cutting windows, doors, and reinforcing the structure adds to the cost. Contractors charge $50–$150 per hour for customization. For a large container house, structural changes alone can cost $150,000–$175,000. DIY enthusiasts can save significantly, with costs dropping to as low as $10,000.

Labor Costs

Labor costs depend on your location and the complexity of your design. Hiring professionals ensures quality but increases expenses. Contractor fees for customization range from $50 to $150 per hour. For a large project, labor can account for a significant portion of your budget.

Permits and Approvals

Securing permits is essential. Building permits typically cost $500 to $2,000, depending on local regulations. Property taxes also vary, so check with your local authorities to avoid surprises.

Utilities and Infrastructure

Connecting utilities to your shipping container home can be costly. For example:

These costs depend on your location and whether you're building in a rural or urban area.

Interior Finishing

Interior finishing transforms your container into a cozy home. This includes insulation, flooring, and fixtures. Costs vary based on materials and design choices. For example, using reclaimed wood or budget-friendly tiles can reduce expenses.

Factors Influencing Shipping Container House Cost

When planning a shipping container home, several factors can significantly impact the overall cost. Let me break down the key elements that influence your budget.

Location and Land Prices

The location of your project plays a major role in determining the shipping container house cost. Urban areas often come with higher land prices due to demand and limited space. On the other hand, rural areas may offer cheaper land but could increase transportation and installation costs.

Proximity to shipping ports or industrial zones can reduce container prices.

Local building codes and regulations may require additional permits, adding to your expenses.

The cost of goods and services in your area also affects your budget.

Choosing the right location is crucial. It’s not just about the land price but also the hidden costs tied to the site.

Size and Number of Containers

The size of your shipping container home directly impacts the cost. A larger home requires more containers, which increases both material and labor expenses. For instance, a single-container studio will cost far less than a multi-container family home.

If you’re aiming for a spacious design, consider how many containers you’ll need and whether they’ll be new or used. Used containers are cheaper but may require repairs, which can add to your budget.

Design Complexity

The complexity of your design can make or break your budget. Simple designs with minimal modifications are more affordable. However, intricate layouts with multiple containers, custom windows, and unique features can drive up costs.

Structural reinforcements for complex designs add to the price.

Challenges like insulation and limited space require creative solutions, which can increase expenses.

Keeping your design straightforward can help you manage costs effectively.

Material Choices

The materials you choose for your shipping container home significantly affect the overall cost. For example, corten steel containers are durable and weather-resistant, making them a popular choice. However, they come at a higher price.

Opting for high-quality materials may seem expensive upfront, but it saves money on repairs in the long run.

Local Labor Rates

Labor costs vary widely depending on your location. Urban areas with higher living costs often have more expensive labor rates. Hiring skilled professionals ensures quality but can strain your budget.

If you’re looking to save, consider taking on some DIY tasks. However, leave complex jobs like structural modifications to the experts. Balancing professional help with personal effort can help you stay within your budget.

Hidden Costs of Shipping Container Homes

Insulation and Climate Control

Insulation is one of the most overlooked expenses when building a shipping container home. Steel walls conduct heat and cold, making proper insulation essential for energy efficiency. Without it, heating and cooling systems will work overtime, driving up energy bills. The climate where you build plays a huge role. In colder regions, you’ll need thicker insulation to keep the interior warm. In hotter areas, reflective coatings or spray foam insulation can help maintain a comfortable temperature. Skimping on insulation might seem like a way to save, but it often leads to higher long-term costs.

Insulation prevents heat transfer through steel walls.

Poor insulation increases energy demand, raising utility bills.

Climate-specific insulation ensures year-round comfort.

Foundation and Site Preparation

Preparing the site and laying a foundation are critical steps that many underestimate. A case study from South Africa highlights this. The project involved clearing and leveling the land, excavating, and pouring reinforced pier foundations. These foundations supported the container corners and provided extra stability for longer units. On average, a concrete foundation costs $10 per square foot. Site preparation costs vary depending on the terrain and soil condition. Neglecting this step can lead to structural issues down the line.

Transportation and Delivery

Getting your containers to the site isn’t as simple as it sounds. Transportation costs depend on the distance from the supplier to your location. If you’re building in a rural area, expect higher delivery fees. Additionally, you may need cranes or forklifts to unload and position the containers, which adds to the expense. Always factor in these logistics when planning your budget.

Maintenance and Repairs

Shipping container homes require regular maintenance to stay in top shape. Over time, steel can rust, especially in humid climates. You’ll need to invest in rust-proof coatings and periodic inspections. Repairs, such as fixing leaks or replacing damaged panels, can also add up. While these homes are durable, they’re not maintenance-free. Planning for these ongoing costs will save you from unpleasant surprises.

Unexpected Delays

Delays can wreak havoc on your budget. For example, container shipping reliability dropped from 75.3% in July 2021 to 35.6% in July 2022. This means your containers might not arrive on time, delaying the entire project. Each day of delay reduces the likelihood of a shipment being traded by 1% and decreases its value by 0.8%. Weather, labor shortages, or permit issues can also cause setbacks. Building a buffer into your timeline and budget is crucial to avoid financial strain.

Cost-Saving Tips for Shipping Container Homes

Use Pre-Owned Containers

Using pre-owned containers is one of the easiest ways to save money when building a container home. These containers are not only cheaper than new ones but also promote sustainability by recycling materials. For example, reusing shipping containers reduces embodied energy, which lowers overall construction costs. Additionally, this method minimizes the consumption of resources like sand and water, making it an eco-friendly choice. By opting for pre-owned containers, you can significantly cut down on expenses while contributing to sustainable living spaces.

Simplify the Design

A simple design can drastically reduce your budget. Complex layouts often require additional structural reinforcements, which increase costs. Instead, consider using the container’s natural features to your advantage. For instance, the flat metal roof eliminates the need for extra roofing materials, and the durable corrugated walls can serve as-is. Even the existing plywood floors can be sealed with epoxy to save on flooring costs. Simplifying your design doesn’t just save money—it also speeds up the construction process.

DIY Certain Tasks

Taking on some DIY tasks can lead to significant savings. For example, you can handle painting, insulation, or even basic interior finishing yourself. This approach not only reduces labor costs but also allows you to customize your home to reflect your personal style. I’ve seen people create unique, sustainable living spaces by repurposing materials and adding their own creative touches. Plus, the satisfaction of building something with your own hands is priceless.

Tip: Leave complex tasks like structural modifications to professionals to ensure safety and quality.

Source Local Materials

Sourcing materials locally is another effective way to save money. Local suppliers often offer lower prices compared to imported goods, and you’ll avoid hefty transportation fees. For instance, purchasing used containers or reclaimed wood from nearby vendors can significantly reduce costs. This strategy also supports local businesses and reduces your project’s carbon footprint, aligning with sustainability goals.

Plan and Budget Effectively

Proper planning is the cornerstone of affordability. Start by creating a detailed budget that includes all potential expenses, from container costs to hidden fees like permits and site preparation. Allocate a buffer for unexpected costs to avoid financial strain. By planning ahead, you can make informed decisions and prioritize spending on essential features. Remember, a well-thought-out plan ensures your dream home stays within reach.

Note: Shipping container homes cost significantly less than traditional homes, averaging $75–$90 per square foot compared to $150–$200 per square foot. This makes them an attractive option for budget-conscious builders.

Shipping container homes offer a unique blend of affordability and sustainability. Key cost components include freight charges, insurance, port fees, customs duties, and handling charges. Budgeting for hidden costs like insulation or site preparation is essential. To save money, I recommend consolidating shipments, negotiating with freight forwarders, and leveraging technology for cost management. These strategies make container homes a smart, eco-friendly choice.

FAQ

What permits do I need for a shipping container home?

You’ll need building permits, zoning approvals, and inspections. Always check local building regulation laws to ensure compliance and avoid costly fines.

How long does it take to build a shipping container home?

It typically takes 3–6 months, depending on the design and complexity. Planning ahead and hiring experienced professionals can speed up the process.

Are shipping container homes durable?

Yes, they’re made of corten steel, which resists corrosion and harsh weather. Proper maintenance, like rust-proof coatings, ensures they last for decades.