Product Link:

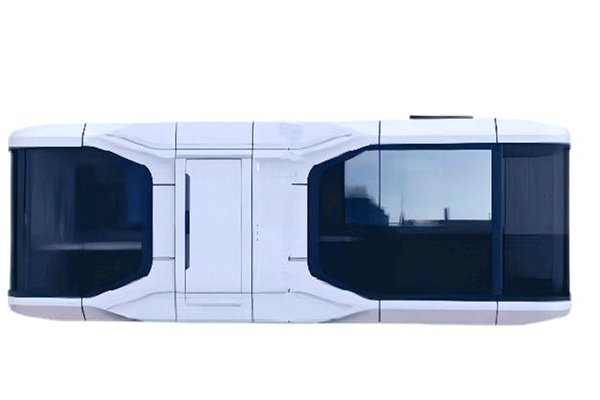

https://www.capsulehousemanufacturer.com/products-creative-container-house.html

Container houses are also a kind of small buildings. When we build this kind of building, we must meet its installation technical requirements, so as to ensure that there will be no problems in the subsequent use. I will explain the installation technical requirements in this regard.

1. Basic installation

The installation of container houses is the same as building buildings. First, the surroundings and partitions of the installation site should be leveled. The material used for leveling is preferably reinforced concrete, which can be stronger and stronger; then erect the pillars and connect the skeleton with transverse beams; then lay the floor. If multiple layers are required, continue to install upwards, fix it, and then install the roof truss and roof panel; finally install the doors and windows, pull the vertical support and other components, and install the small hardware necessary for the matching sanitary ware.

2. Check quality and safety

Since the container house is a light steel structure, it is similar to the heavy steel structure factory building during installation. Therefore, during the construction of the mobile house, each process will be covered by the next process, so many parts cannot be inspected after all are completed. In view of this, after the installation of the foundation part of the mobile house is completed, it is necessary to carefully check whether each place is firmly connected to ensure the quality and safety of the mobile house.

3. Concealed engineering installation

"Concealed engineering" refers to the engineering installation of plumbing and electrical circuits. Every installation step in the container house cannot be sloppy, and any flaws in any link will bring serious economic losses. When installing concealed engineering, attention should be paid to the process and material use of waterproof construction to ensure safe living.

What are the technical requirements for the installation of container houses?

First of all, it is necessary to pay attention to the testing of the sealing, insulation, waterproofness, fire resistance and moisture resistance of the container; second, the container must be replaced after the service life is up. There are many container villas on the market. How long is the life of container villas? The service life of simple iron box containers is mostly within 5 years, and customized container houses are basically used for more than 30 years, that is, the life of container villas is 20-30 years.

Simple container houses, because the materials are not the best, the service life is also relatively short, and it is good to be able to last for seven to eight years. This is what you must know! However, container houses are convenient to use, and disassembly and recycling are environmentally friendly and economical! However, professional guidance must be provided when installing mobile houses!

Mobile houses are usually used for temporary construction houses for on-site operations such as roads, railways, and construction; municipal, commercial and other temporary housing, such as: temporary offices, conference rooms, headquarters, dormitories, temporary shops, temporary schools, temporary parking lots, temporary exhibition halls, temporary maintenance departments, temporary distribution rooms, temporary gas stations, etc.; other temporary housing areas: such as temporary housing for military logistics, emergency rescue rooms, sterile testing rooms, isolation rooms, communication transformer rooms, etc.

The hidden construction of container houses refers to the site covered by the next process after the previous process is completed, which cannot be inspected after the previous process is completed. To do house decoration, "hidden engineering" is the key. If this is not done well, no matter how beautiful the surface decoration is, it is futile.

"Hidden engineering" can be divided into water installation, electrical installation, moisture-proof and waterproof. Each of these projects cannot be ignored. If there is a problem in any link, it may bring serious economic losses and even harm personal safety. Waterproof construction process and material identification to avoid unnecessary economic losses and injuries.

In order to ensure the quality of the house, these installation technical requirements must be met, otherwise the probability of danger is very high.

What are the advantages of container house construction?

a) Faster speed

Modular container construction is 40-60% faster than traditional construction methods, and the delivery time can be reliably predicted and controlled.

b) Cost-effectiveness

In the past, the cost of general modular construction technology was higher than that of traditional construction technology (such as brick-concrete structure, etc.). Now, new modular container buildings use innovative technologies to reduce the cost of modular construction. Compared with traditional brick-concrete buildings of the same scale, the economic benefits are better.

c) Reduced dependence on skilled workers

Modular container houses can be manufactured in factories, with specialized division of labor, and a large number of semi-skilled workers can be used, thus reducing the dependence on increasingly scarce skilled workers.

d) Safe construction method

Practice has proved that modular container construction is a safe construction method. Compared with traditional construction methods, it uses fewer components.

e) Better quality

The modular container building modules are manufactured in a factory. The factory environment and indoor construction conditions will ensure that their quality is easier to control and improve, defects are reduced, and product reliability is improved. At the same time, there is high production efficiency.

f) Environmental protection and sustainable development

Modular container buildings are environmentally friendly: off-site parts require much less energy than on-site parts. During on-site construction, waste can be reduced by 70%. Modular container buildings have better sound insulation and heat insulation than traditional buildings, and daily energy consumption can be reduced, meeting the requirements of sustainable development.

g) Reduced interference

The construction period of modular container buildings is short, which reduces interference with nearby businesses and residents.