Product Link:

https://www.capsulehousemanufacturer.com/products-creative-container-house.html

Construction process and installation of container houses

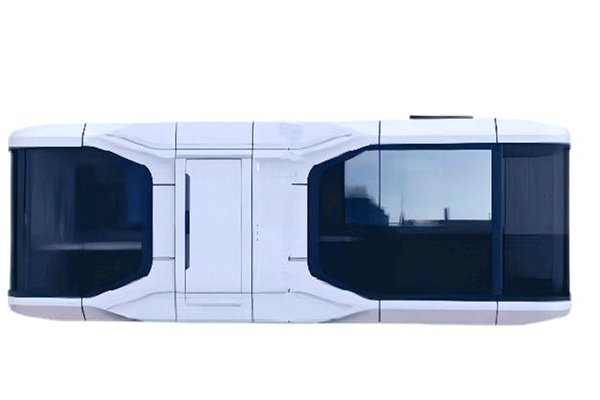

As a constituent unit of structured buildings (container buildings), containers can be used as a single room or in combination with multiple boxes, with various shapes. The high thermal insulation and heat insulation performance of container houses improves the overall quality of the outdoor office environment. Due to the many advantages of container buildings, container houses are widely used in construction site offices and residences, factory buildings, outdoor work sites, rooftop additional facilities and other fields.

Container houses are simple to manufacture, quick to assemble, easy to move, safe and environmentally friendly. So how are container houses built?

1. The integral hanging series container houses adopt a light steel structure system, and the walls are covered with composite high-efficiency insulation wall panels. All wall panels and accessories can be folded and packed, and are easy to install, suitable for long-distance large-scale transportation and export shipping.

2. The roof, ground, and circuit systems are completely prefabricated in the factory, making on-site installation convenient and fast, shortening the time interval from building the house to use.

3. The steel structure system enables the house to have excellent resistance to wind speeds of 120km/h; the lightweight structure enables the house to show good integrity when encountering earthquake disasters that are stronger than the earthquake fortification intensity of 8 degrees.

4. The house can be transported as a whole or compressed and packaged for transportation

5. The on-site foundation production is small and can be used after being transported to the site.

6. The house can be recycled and can be used sustainably for 20 years without generating any construction waste during use.

7. The roof adopts a structural waterproof design to enhance the airtightness and watertightness of the house.

8. When the house leaves the factory, you can choose to add decorative accessories such as awnings according to actual applications. The construction of container houses is so simple and fast. Compared with ordinary outdoor buildings, container houses have rare construction advantages.

Containers are a kind of component tool that can load packaged or unpackaged goods for transportation and facilitate loading and unloading with mechanical equipment. The greatest success of containers lies in the standardization of their products and the complete transportation system established thereby.

So how are container houses installed?

1. Laying out the lines

According to the dimensions on the drawing, use the ink fountain to pop up the installation position line of the board house on the board house foundation, and use the Pythagorean chord rule to square it. Use a horizontal tube to give relative elevation points around the foundation, and the number of points should be no less than 2 points on each ground beam.

2. Ground beam installation

Put the ground beam on the foundation of the board house, align the ground beam according to the installation position line of the board house, and the position of the ground beam and the axis is allowed to deviate by 3mm. Align the ground beam elevation according to the relative elevation given around the foundation. When adjusting the ground beam elevation, the highest point foundation should be used as the reference, and the horizontal ruler and variable ruler should be used.

3. Column installation

Lift the column to the installation position and erect it, so that the card code under the column is stuck on the lowest ring beam. The corner column, the middle column, and the gable column are all welded and formed, and the walkway bracket can be installed with the column.

4. Floor installation

The floor slabs should be laid with mortar. If there are cracks between the slabs, they are not allowed to be installed and used. The surface of cement or fine stone concrete should be compacted and polished. No defects such as cracks, peeling and sanding are allowed.

5. Wall installation

According to the layout diagram, the first wall of the container office must be corrected. The corners and positive corners of the umbrella wall are sealed with angle aluminum. The connection between the slabs is connected with I-shaped aluminum. Each wall must be vertical, the caulking depth is consistent, neat and clean. The wall surface should be clean and consistent in color. The slab seams are neat, the nailing surface should be consistent from top to bottom, and self-tapping bolts are used in necessary parts. Mark the door and window positions of the container conference room according to the design drawings, cut the door and window opening positions with a cutting machine, install the windows and doors according to the door and window opening positions, and install the ceiling of the bottom floor of the container mobile house.

6. Window installation

Installation order: upper and lower closing of windowsills, window frame installation, window sash installation, window lock hook glue. Draw the vertical center line and horizontal center line on the window opening. During installation, ensure that the center line of the window frame coincides with the center line drawn on the window opening. Place the window frame in the side groove of the column, and use a steel tape measure to measure the length of the diagonal line of the inner corner of the window frame so that the two diagonal lines are equal in length. Adjust the window frame to make it horizontal and vertical. Install the window sash and the window lock hook. According to the position of the lock hook on the window sash, install the lock hook on the window cabinet, and ensure that the positions of the two lock hooks are consistent, the installation is firm, and the switch is flexible.

7. Door installation

Installation sequence: door frame, door handle, door head plate, door leaf (hinge), lock, latch, glue. The door head plate is embedded between the door frame and the door handle, and is sealed with glass glue on all sides.Install the hinge on the frame according to the position of the hinge on the door leaf, and ensure that the position of the frame and leaf hinge is consistent, the upper and lower hinges are on the same axis, and the frame and leaf hinges must not be reversed. According to the position of the door lock on the door leaf, install the lock plate, and ensure that the lock body tongue on the door and window matches the position of the lock plate on the door frame.

8. Installation of internal partition wall panels

Construction sequence: wall position line internal partition wall installation internal partition glass door glue. Use the vertical line method to lay out the installation position line of the inner partition board. The allowable deviation of the inner partition glass installation and the center displacement of the roof truss should be less than 2.0mm. When installing the inner partition glass, install the inner partition glass from one side of the wall to the other side, and use the ruler to check the verticality, straightness and misalignment of the inner wall board. The gaps of the inner partition board are sealed with glass glue, and the paint film damaged during transportation and installation is repainted.

How is the container house installed?

1. The enclosure board of the container mobile board house should not be obviously deformed or damaged; the strong bolts, waterproof washers, metal washers, nylon sleeves, etc. are complete and the connection is reliable; the sealant is complete and effective. 2. The panel of the container mobile board house should be installed firmly, the eaves are straight, and the overlap angle of the board is accurate and equal. The attached wall panel should be installed with accurate board arrangement and flat surface; the embedded wall panel should be installed flat, the upper and lower overlap seams should accept the tongue-and-groove seam, and the outer side board should overlap downward. 3. The electrical lines in the container mobile board house should be laid openly with PVC pipes, and the wiring should be neat and beautiful; the lines should not be insulated and aged, and the extension should not be used. 4. Fire resistance: The fire protection distance should meet the requirements of the plan and the standard, and the fire passage should be clear; the fire hydrant and fire extinguisher should be installed and arranged in accordance with the plan requirements and the structure should be fair; the fireproof and heat insulation measures in fire-using places such as kitchens should be effective. 5. Lightning protection: The lightning protection grounding should meet the requirements of the plan and the standard; the grounding resistance should be checked and qualified. 6. Corrosion resistance: Steel components should be painted completely and rust-free, and the exposed bolts should be properly protected; the anti-corrosion measures under strong corrosion conditions should meet the requirements of the plan; the surrounding area of the mobile room should be drained smoothly, and no debris is allowed.

Quality requirements for container houses

1. Steel components

The surface of the structural parts is clean, free of oil, mud, sand, dust and other debris. The coating damaged by the components during transportation, storage and installation should be repainted. All fasteners of the connection nodes should be tightened without looseness. 2. Wall panels and roof tiles

Roof tiles and wall panels should be flat and clean, with straight joints, straight vertical and horizontal joints, straight eaves and lower ends of the wall, no wrong drilling, uniform and neat joints, tight and no warping. Gable edge panels and ridge tiles should be straight, fixed reliably, and not loose.

3. Hardware

Hardware should be reliably assembled, and there should be no looseness or jamming at the sliding parts that affect the performance. The outer contour should not have cracks, burrs, mechanical damage, and the paint film coating should not fall off. The end of the nail should be round and smooth, and should not be higher than the surface of the assembly. The rivet should be firm and loose. The lock and window hooks and latches should be flexible to open and close, without obvious defects that affect the appearance.

4. Allowable deviation of door and window installation

The door and window frames should be installed horizontally and vertically, with consistent height and plane. The connection between the frame and the column should be firm, without shaking, and the gap should be uniform. The surface of doors and windows should be flat, smooth, and free of scratches and dents.