Shipping container homes are popular because they are cheap and green. The market might grow from $60.02 billion in 2024 to $95.74 billion by 2033. This is due to expensive regular houses and people caring more about the planet. But mistakes like picking the wrong container size or changing too much can make them unsafe. Good planning and learning are key to building a safe and useful container home.

Key Takeaways

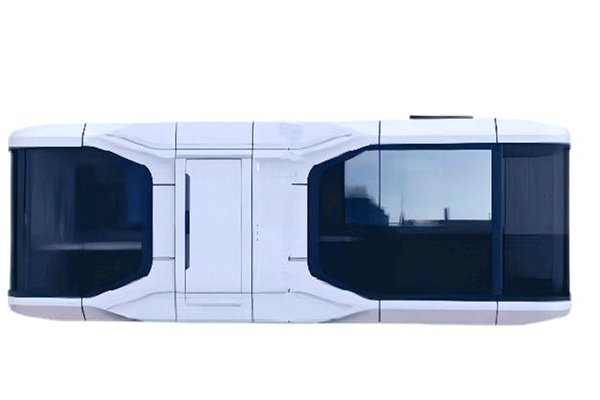

Pick the right size for your container home. A 20-foot container is good for small homes. A 40-foot container fits families better. Match your needs to your budget.

Check containers closely for rust, dents, or harmful chemicals. Look at their ratings to check their condition. Make sure they are safe before buying.

Learn about local zoning rules and building codes. Find out the laws in your area to avoid problems. This helps keep your container home safe and legal.

Picking the Best Size for Your Shipping Container Home

How size affects use and design

When I looked into container homes, I saw how size matters. A small container can feel tight, but a big one may cost too much. The size also changes how you can arrange the inside. For instance, a 20-foot container is great for a small office. A 40-foot container gives more space for a family home.

The size you pick also changes how much you spend. Common sizes like 20-foot and 40-foot are cheaper than custom ones. But creative designs to use space better can raise costs for work and planning. Balancing your needs and budget helps you choose wisely.

Advice for picking the right container size

To find the right size, start with a clear goal. Are you making a small getaway, a big family house, or an office? Once you know, think about how much space you need. Plan for furniture, storage, and walking areas.

Money is another big thing to think about. Bigger containers cost more and may need extra changes. Also, check if the container can be moved and delivered easily.

Here are some helpful tips to make the most of your design:

By using these tips, you can pick the right container size. This way, your home will fit your needs and still look great.

Checking Shipping Containers for Problems

Usual problems like rust, dents, and leftover chemicals

When I check containers, I look for clear damage. Rust is a big problem because it makes containers weak. Dents can also be an issue. Even small dents can harm the container's strength. Another concern is leftover chemicals. Some containers carried harmful stuff before, leaving dangerous residues.

To know a container's condition, I use industry ratings. Here's a table showing container types and their common problems:

By knowing these ratings, I can spot issues fast. This helps me decide if a container is worth buying.

Ways to check if your container is strong

Making sure a container is strong is very important. I always check the corners and edges first. These spots hold the most weight and often rust. I also look at the floor for damage. If the floor feels soft, it might need fixing.

There are rules to help with inspections. For example, the UCIRC and IICL-6 guides explain what to check. Here's a table of some key rules:

If you're unsure about a container, hire an expert. They can find hidden problems and check safety. Doing this can save money and make sure your container home is safe and strong.

Navigating Local Planning Regulations and Building Codes

Knowing zoning laws and building codes

When I learned about shipping container homes, I saw how vital it is to know local rules. Zoning laws decide what you can build and where. They control land use, building size, and placement. Building codes focus on safety rules for construction. These include structure strength, wiring, and plumbing. Ignoring these rules can cause delays or legal trouble.

Here’s a simple guide to key rules you’ll face:

Each state has its own rules. For example:

California has strict earthquake safety rules and needs permits for all major work.

Texas uses the International Residential Code (IRC) but has easier rules in some cities like Houston.

Florida focuses on wind safety because of hurricanes, with extra rules in places like Miami-Dade County.

Steps to follow local rules

To make sure your shipping container home follows local rules, try these steps:

Learn Zoning Laws: Check your area’s rules about container homes, like size and placement limits.

Hire Experts: Get help from an architect or designer to meet building codes.

Gather Documents: Collect plans, engineering reports, and proof you own the land.

Get a Permit: Send all needed papers to your local office for approval.

Plan Inspections: Set up checks during building to ensure you follow the rules.

Check Strength: Ask a structural engineer to make sure changes to the container are safe.

By doing these steps, you can avoid problems and keep your home safe and legal. Planning ahead and working with experts will save time and stress.

Fixing Insulation Problems in Shipping Container Homes

Why insulation matters for keeping temperatures comfortable

When I learned about container homes, I saw how vital insulation is. Metal walls let heat and cold pass through easily. This makes the inside too hot in summer and freezing in winter. Without good insulation, living in a container home is tough.

Here are some insulation problems I noticed:

Steel walls hold heat and cold, making it hard to stay comfy.

Airtight designs trap moisture, causing condensation and mold.

Picking the wrong insulation adds costs and creates more issues.

Good insulation stops heat transfer and controls moisture. It keeps the home cool in summer and warm in winter. Using high R-value materials also saves energy and lowers bills over time.

Top insulation materials for different weather

The best insulation depends on your home’s location. Some materials work better in certain climates. Here’s a simple guide:

For most homes, closed-cell spray foam is the top choice. It sticks to metal walls, seals gaps, and stops condensation. In tropical areas, spray foam insulation is better for handling high humidity.

When insulating, think about material and setup costs. Some options cost more at first but save money later by cutting energy bills. Avoid bad insulation choices to prevent extra expenses and poor results.

Avoiding Over-Modification Risks

Why too many changes can cause problems

When I learned about container homes, I saw how too many changes can cause trouble. Cutting big holes for windows or doors makes the container weaker. It can’t hold heavy weight or handle bad weather as well. For example, removing too much steel means you’ll need to add supports like steel beams. These supports cost more money and take extra time to put in.

Cutting large openings for windows or doors can weaken the container, making it less safe in storms or heavy loads.

I’ve heard of people making too many changes without planning. This caused containers to break or fail safety checks. To avoid this, it’s important to know how each change affects the container’s strength.

How to stay safe when making changes

To keep your container home strong, follow these tips:

Hire experts to make sure changes don’t weaken the container.

Follow local rules to meet safety and legal standards.

Add supports to keep the container strong after changes.

Use safe materials like fire-resistant ones and add good airflow.

Also, make sure the container meets ISO rules before using it. These rules check if the container is strong and stable. Every change affects the container differently, so plan carefully. Working with experts helps keep your container home safe and useful.

By thinking ahead and focusing on safety, you can build a home that looks great and stays strong.

Finding Reliable Contractors for Your Shipping Container Home

Why hiring the wrong contractor is risky

When I learned about shipping container homes, I saw the risks of hiring unskilled builders. Picking the wrong contractor can cause bad work, delays, or safety problems. Some builders don’t know how to handle container construction. They might cut too much steel or use the wrong materials, making the home weaker.

Untrained contractors often don’t understand local building rules. Changing containers to meet these rules can be tricky. Only skilled builders know how to do it right. Even DIY fans often need expert help because container homes need special skills. If a contractor isn’t experienced, they might skip steps, leaving you with an unsafe home.

Steps to find the best contractor

Finding a good contractor takes time, but it’s important. I always check if they’ve worked on container homes before. Experienced builders know the challenges and how to fix them. I also choose someone who cares about my project. This way, they’ll focus on doing quality work.

Here’s how I pick contractors:

Ask for References: Talk to past clients about their experience.

Check Licenses and Certifications: These show the contractor follows industry rules.

Review Portfolios: Look at their past work to see their style.

Get Detailed Quotes: Clear estimates help avoid surprise costs.

By following these steps, I’ve found skilled contractors who do great work. Taking time to choose the right builder ensures your container home is safe, strong, and built to last.

Making homes from shipping containers has special challenges, but planning helps. Always work with experts for design and permits to avoid problems. Builders who follow rules usually do a better job. Writing down what you learn can make future projects easier. With good planning, you can build a safe and useful home.

FAQ

What are the hardest parts of building a container home?

The hardest parts are insulation, changes to the structure, and following local rules. Finding skilled builders is also very important for success.

Can I put a container home anywhere?

No, you can’t build it just anywhere. Local zoning rules decide where you can build. Always ask your local planning office before starting.

How long does it take to make a container home?

The time depends on the design and changes needed. A simple home might take a few months. Bigger projects take longer because of permits and building work.